Best High Energy Screeners for Powdered Metal Process

Elcan’s Hi-Sifter is the latest breakthrough in advanced screening technology. The Hi-Sifter high energy screeners excel in the food, pharma, and additive manufacturing industries and unlike other vibratory screeners, the Hi-Sifter requires no anti-blinding or screen cleaning devices to achieve fine particle separation. The material only sees a highly polished stainless steel surface and no other possible contamination surfaces.

In addition, the high volume of energy being transferred to the screen allows hard to screen metal alloys to flow seamlessly. The machine also has a strong vertical vibration that translates to high rates of efficiencies and throughputs without any blinding. The removal of any potential for contamination within the machine, explosion proof designs and high energy make the Hi-Sifter the precise fit for companies looking to add screening machinery to their manufacturing plants.

Screening Metal Powders

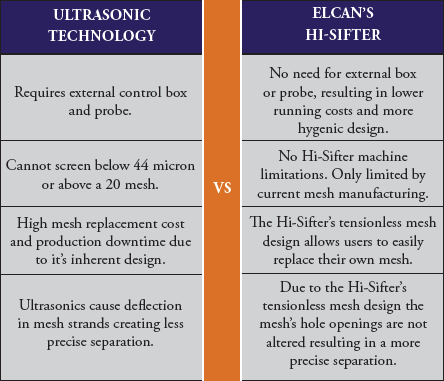

Ultrasonics traditionally work by stimulating each wire within the mesh to vibrate independently from the machine itself. Where ultrasonics fall short is that it will not work with corse or ultra-fine mesh. It also requires external hardware and is very costly to repair/replace damaged mesh. The Hi-Sifter solves these shortcomings. The Hi-Sifter high energy screening technology not only vibrates in the X and Y axis like standard screeners, but also transfers significant force in the Z axis, ensuring that the screen will not blind even at as fine as 10 micron. The system also allows for easy screen changes to be completed at the plant level eliminating the high cost and potential downtime that comes from sending out for re-screening.

Contract Manufacturing Metal Powders

Elcan Industries’ state of the art toll manufacturing facility features 9 full-scale bays dedicated to contract manufacturing and testing. In addition to our advance screening technologies, we have an Electro Magnetic Separator, bulk-to bag packaging area, blending/mixing machinery and a newly installed Elbow Jet Air Classifier. Unlike most OEMs, we run these machines in our factory every day. This daily practice has given Elcan the hands-on experience and know-how that is invaluable to our customers. All of the equipment that Elcan offers for sale is available for use in our facility. By the time our customers purchase equipment for their factory to run products they were tolling with us, the bugs are all worked out and the problems are eliminated.

Powder Metal Process Video

Elcan also offers a free test day to any new customers looking to trial their material on the equipment offered. The ability to test products and to toll process it, allows for companies to test new markets and have confidence in the equipment they are purchasing before making a capital equipment decision.